Is the warning light for your How to Fix Electronic Throttle Control? You might be upset or worried about what this means for your car.

The good news is that you can fix a lot of electronic throttle control (ETC) problems without having to pay a lot of money to go to the mechanic. You’ll learn how to fix and diagnose your ETC system in easy steps. You can save time and money by following these useful tips, which include cleaning the throttle body, checking the wiring, and even resetting the system yourself.

Read on to learn how to take charge of how your car works and get back on the road with confidence.

Reasons that happen a lot

Knowing what usually causes problems with electronic throttle control makes it easier to figure out what’s wrong quickly. These problems have an impact on how well and safely a car works. Finding the root cause helps with the right repair and upkeep.

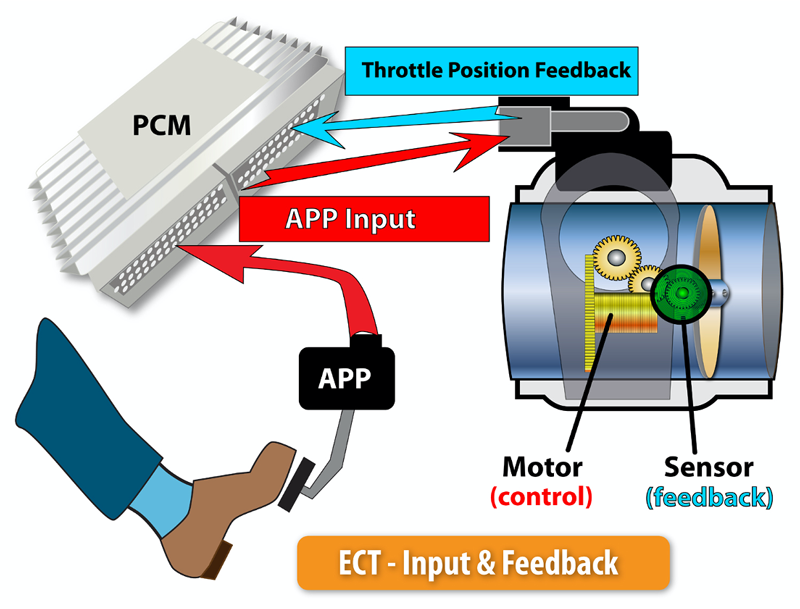

Problems with electricity

Throttle control failures are often caused by electrical problems. The signal is interrupted by wiring issues, loose connections, or blown fuses. Problems can also happen because of broken wiring in the throttle motor or sensors. You can find these problems by testing the electrical system.

Wear and tear

Parts inside the throttle system wear out over time. The throttle plate, motor, and sensors wear down over time. This wear can make things slow to respond or not work at all. Regular inspections help find worn-out parts early on.

Pollution

The throttle body doesn’t work right when dirt, dust, and oil build up inside it. The throttle plate and sensor areas are where contaminants stick. This makes sensors stick or give wrong readings. Cleaning the throttle body usually fixes the problem.

Problems with the control system

The electronic control unit (ECU) controls the throttle. Faults can happen because of bugs in the software or mistakes in calibration. The ECU may need to be reset or reprogrammed from time to time. For control system problems, you need special diagnostic tools.

First Diagnosis

The first step in fixing problems with electronic throttle control is to make a diagnosis. It helps find the main problem before any work is done. This step saves time and keeps you from having to replace parts that don’t need to be. A clear diagnosis tells you what repairs to make. It also makes sure that the vehicle is safe and works properly after the repair.

How to Use an OBD-II Scanner

A vehicle’s computer sends data to an OBD-II scanner. It finds problems with the electronic throttle system. Connect the scanner to the car’s diagnostic port. Turn on the ignition, but don’t start the car. The scanner will show real-time data and any error codes that have been saved. This tool quickly finds the exact problem.

Checking the Warning Lights

The warning lights on the dashboard show that there is a problem with the throttle control. The light for electronic throttle control often looks like a small engine or throttle symbol. If this light stays on or blinks, there is a problem. See if other lights, like the check engine light or the ABS light, also come on. These clues help us figure out what the fault is.

Finding Trouble Codes

Trouble codes give you specific details about the problem with the throttle system. Most codes start with a “P” and then have numbers. For instance, P2135 means there are problems with the throttle sensor. Make a list of all the codes the scanner finds. Looking into these codes can help you figure out which sensors or parts need work. Before replacing or fixing parts, this step is very important.

Looking at it visually

The first step in fixing problems with electronic throttle control is to look at them. It helps find clear problems that make the throttle respond slowly. Checking carefully can save you time and money before you have to do more repairs.

Take a close look at each part of the throttle control system. Little things like broken parts or loose screws can make big problems. When you’re in a tight space, use a flashlight to see better.

Looking at the wiring and connections

Look for cuts, burns, or rust on all of the wiring. Wires that are broken can stop signals from getting to the throttle system. Check that the connectors fit snugly and don’t show any rust. Warning lights often come on when connections are loose or dirty.

Gently wiggle the wires to find breaks that are hard to see. Change out any wires that look old. Use electrical contact cleaner to clean connectors and make the flow better.

Checking the sensor on the accelerator pedal

The throttle body gets signals from the accelerator pedal sensor. These signals can be blocked by dirt or damage. Take off the sensor cover and look for cracks or dirt that has built up.

Push the pedal and watch the sensor move smoothly. You need to replace sensors that are stuck or broken. To be sure, use a multimeter to check the continuity of the sensor wires.

Checking the throttle body

The throttle body controls how much air goes into the engine. It can get blocked by dirt and carbon deposits. Open the throttle body and check for dirt or buildup inside.

Make sure the throttle plate can move freely. Sticking plates make the throttle respond slowly. Use the right cleaner to clean the throttle body and get it working again.

Cleaning the throttle body

Cleaning the throttle body is an important part of fixing problems with electronic throttle control. Dirt and carbon buildup can make it hard for air to flow and make the throttle plate stick. This makes the engine run poorly and causes warning lights to come on on the dashboard. Cleaning the throttle regularly makes it work smoothly again and makes the car respond better.

You can do it with just a few simple tools. It means taking off the air intake duct, spraying throttle body cleaner on it, wiping off the carbon deposits, and checking how the throttle plate moves. To avoid damage, make sure to follow the steps exactly.

Taking out the air intake duct

To begin, open the hood and find the duct for the air intake. It links the throttle body and the air filter box. To loosen the clamps that hold the duct, use a socket wrench or a screwdriver. Gently pull the duct away from the throttle body. Put it aside so you can see the throttle body clearly.

How to Use Throttle Body Cleaner

Choose a cleaner for the throttle body that is made for this purpose. Use the cleaner to spray the throttle plate and the inside of the throttle body bore. Don’t use strong chemicals that could hurt sensors. Let the cleaner sit for a minute so it can break down dirt and deposits.

Removing Carbon Buildup

Use a brush or a soft cloth to gently wipe away the carbon buildup. Clean the walls of the bore and both sides of the throttle plate. Get rid of all dirt and residue that you can see. While cleaning, don’t try to open or close the plate. Keep spraying and wiping until the throttle body is clean.

Making sure the plate moves

After cleaning, check the movement of the throttle plate by lightly pushing it with your finger. It should be able to move without getting stuck or having to push against something. If it feels stiff, clean it again or check for mechanical problems. Before starting the engine, make sure the air intake duct is securely attached and all clamps are tight.

Reset and learn how to do things again

After fixing the electronic throttle control, it’s very important to reset and relearn the procedures. These steps help the car’s computer get used to the position of the throttle body and make sure everything runs smoothly. If you don’t do this, the throttle might not work right, which could lead to bad performance or warning lights. There are many ways to reset and relearn, depending on the car and the tools you have.

Method of Key and Pedal Sequence

To reset the throttle control system, this method uses the gas pedal and ignition key. First, put the car in park on a flat surface and set the parking brake. Set the ignition key to “ON” but don’t start the engine. After that, push the gas pedal all the way down and keep it there for about ten seconds.

Slowly let go of the pedal and wait a few seconds. Do this press-and-hold sequence three times. After the last release, turn on the engine and let it run for five minutes. This lets the computer learn the throttle position again and make the necessary changes.

How to Disconnect the Battery

By cutting power to the vehicle’s electronics, disconnecting the battery resets the throttle control system. Put the car in a safe place and turn off the engine. Take off the negative battery terminal with a wrench. To clear stored data, leave it unplugged for about 15 minutes.

Make sure the battery terminal is securely connected and tighten it. Set the ignition to “ON,” but don’t start the engine yet. Give the system a few seconds to turn on. To finish the relearn process, start the engine and let it run for a few minutes.

Using Relearn with a Scanner

A professional scan tool can do a throttle relearn with great accuracy. Plug the scanner into the OBD-II port on the vehicle’s dashboard. Set the ignition to “ON” and follow the scanner’s instructions for relearning the throttle.

The tool talks directly to the engine control unit to reset and calibrate the throttle body. This method is usually quicker and more accurate than doing things by hand. If warning lights stay on after trying other things, this is the best choice for complicated throttle systems.

Changing Out Broken Parts

To fix problems with electronic throttle control, you need to replace broken parts. Faulty components cause poor engine performance and warning lights on the dashboard. Finding and replacing these parts makes the throttle work smoothly again. The throttle body assembly and the throttle position sensor are two parts that often need to be replaced.

Replacing the Throttle Position Sensor

The throttle position sensor (TPS) tells you where the throttle valve is. A broken TPS sends the wrong information to the engine control unit. This makes the engine idle roughly, hesitate, and not speed up quickly.

First, unplug the battery to replace the TPS. Next, carefully pull the sensor connector out of the wall. Take out the broken sensor by removing the screws that hold it in place. Put in the new sensor and use screws to hold it in place. Plug the sensor back in and the battery back in. This simple change often fixes problems with electronic throttle control.

Changing the throttle body assembly

The throttle body controls how much air gets into the engine. Throttle control can fail if the throttle body is dirty or broken. These problems go away when you replace the throttle body assembly.

First, unplug the battery and take off the air intake hose. Take the electrical connector off the throttle body. Take out the old throttle body and take off the mounting bolts. Put in the new throttle body and tighten the bolts. Put the air intake hose and electrical connector back together. Finally, put the battery back in.

Replacing the throttle body assembly makes the engine respond better and stops the throttle control warning lights from coming on. For best results, always clean the area around the throttle body before putting it in.

When to Get Help from a Professional

It’s important to know when to get professional help with problems with electronic throttle control. Some problems need tools and skills that only experts have. If you wait too long to act, you could do more damage and pay more to fix it. Knowing the signs of a serious problem helps you make a quick decision.

Warning Lights That Don’t Go Out

If the electronic throttle control light on your dashboard comes on, there’s a problem. If it stays on after basic checks, there is a bigger problem. Professionals use scanners to read exact error codes. Ignoring warning lights all the time could hurt the engine’s performance and safety.

Problems with sensors

The throttle system has sensors that send important information to the engine. Bad sensors send out wrong signals, which can make the car slow down or stop. You need special tools to find out what’s wrong with a sensor. A mechanic can test sensors and replace them the right way.

Difficult problems with the throttle body

Throttle bodies regulate the air entering the engine. It can get stuck or broken by dirt, wear, or broken parts. Cleaning or making small repairs might help for a while. To fix complex problems and keep them from breaking down, you need to hire a professional to fix or replace them.

Advice on how to keep things up

Taking care of the electronic throttle control keeps it working well. Taking small steps can help you avoid big problems and save money. To make your throttle system last longer, follow these easy steps.

Schedule for Cleaning Regularly

To keep dirt from building up, keep the throttle body clean. Dirt blocks airflow and makes the throttle response bad. Every 20,000 miles or as needed, clean the throttle body. For best results, use a throttle body cleaner and a soft cloth. Stay away from strong chemicals that could hurt sensors.

Looking for loose connections

Loose wires make it hard to control the throttle and turn on warning lights. Make sure to check all of the electrical connectors on a regular basis. Check that the plugs fit snugly and that the wires aren’t broken. Carefully reconnect any connectors that are loose or rusty. This easy check can stop throttle control problems from happening early on.

Using Good Replacement Parts

When you need to fix something or replace a part, use original or high-quality parts. Cheap parts break down faster and cause more problems. Good sensors, motors, and cables make sure that the throttle works smoothly. Always check to see if the part will work with your car. This helps keep the system safe and reliable.

Questions That Are Often Asked

What causes problems with electronic throttle control?

Problems with electronic throttle control can be caused by electrical problems, dirty throttle bodies, worn sensors, loose wiring, and control system failures.

How do I get my electronic throttle control system back to normal?

Stop the car and turn off the engine. Without starting, turn the key to “ON.” Press the gas pedal all the way down three times. Let go of the pedal and start the car. This restarts the electronic throttle control system.

If the light for my electronic throttle control comes on, what should I do?

Use an OBD-II scanner to find problems with your car. Check the wiring connections and clean the throttle body. Do a throttle body relearn. If problems keep happening, you should change the throttle body or the sensors. If the electronic throttle control light keeps coming on, get professional help.

How to repair an electronic throttle control sensor?

First, disconnect the battery to fix an electronic throttle control sensor. Take out the broken sensor and put in a new one. Reconnect the wiring and clean the throttle body. To clear codes, use an OBD-II scanner. To reset the system, do a throttle body relearn.

Final Thoughts

Anyone can try these simple steps to fix electronic throttle control. To get rid of dirt and buildup, clean the throttle body. Make sure that all of the wiring is connected properly and that no connections are loose or broken. Carefully follow the key and pedal sequences to reset the system. If the problems don’t go away, get help from a professional mechanic.

Regular maintenance can keep throttle control problems from coming back. Taking action on time keeps your car running smoothly and safely. Keep in mind that small changes can often fix big problems with throttle control. For the best results, be patient and follow the directions.