Have you ever wondered where your rugged Wrangler Jeep is actually made? Knowing the origins of your vehicle can deepen your connection to it and even boost your pride in owning one.

You’ll discover exactly where Wrangler Jeeps are built, what makes these locations special, and how this impacts the quality and performance of your Jeep. Keep reading to uncover the story behind the manufacturing of one of the most iconic off-road vehicles on the planet.

Credit: www.bodyshopbusiness.com

Wrangler Jeep History

The Wrangler Jeep has a rich and exciting past. This vehicle is known for its strength and off-road ability. It has been popular with adventurers and outdoor lovers for decades.

Understanding the Wrangler Jeep history helps us see why it remains a top choice today. The story began with early Jeep models and grew through many changes. Each step added new features and improved design.

Early Jeep Models

The first Jeep was made during World War II. It was a simple, tough vehicle for soldiers. The design focused on durability and ease of repair. Civilians liked its rugged look and strong build.

After the war, Jeep made models for everyday use. These early versions set the foundation for the Wrangler. They combined utility with a unique style that stood out on the road.

Evolution Of Wrangler Series

The Wrangler series began in 1986. It was a new name for Jeep’s off-road vehicles. Each version brought better comfort and technology. The design kept its classic look but improved safety and power.

Wranglers now offer many options for customization. They suit city driving and tough trails. Over time, the series grew to include different sizes and engines. This evolution kept the Jeep popular across generations.

Credit: www.tatebranchhobbs.com

Manufacturing Locations

Wrangler Jeeps are built in several locations around the world. These places focus on quality and precision. Each site plays a key role in making sure every Jeep meets high standards. The production is spread out to serve different markets and keep costs efficient. Let’s explore where these Jeeps come to life.

Primary Production Plants

The main plant for Wrangler production is in Toledo, Ohio, USA. This factory has made Wranglers for decades. It uses modern machines and skilled workers. The Toledo plant handles most assembly and testing. It also builds parts and accessories for Jeep models. This site is central to Jeep’s identity and heritage.

Global Assembly Sites

Wranglers are also assembled in other countries. These sites help Jeep reach global customers faster. Countries like Mexico and India have assembly plants. They build Wranglers for local and nearby markets. This reduces shipping time and costs. These plants follow strict quality controls. The goal is to deliver the same tough Jeep experience worldwide.

Factory Processes

The factory processes behind Wrangler Jeeps are precise and well-structured. Each vehicle goes through careful steps to ensure it meets high standards. The focus lies on assembling parts efficiently while maintaining quality. This balance helps produce durable and reliable vehicles.

Every stage in the factory contributes to making the Jeep strong and ready for tough roads. Skilled workers and modern machines work together on the factory floor. These processes keep the Jeep’s reputation for ruggedness and performance.

Assembly Line Techniques

The assembly line uses a step-by-step approach to build the Jeep. Workers add parts in a specific order, making the process smooth. Robots assist in lifting heavy components and precise installations. This method speeds up production and reduces errors. Each Jeep moves along the line until fully assembled.

Parts like engines, doors, and wheels are fitted carefully. The line design allows quick adjustments for different Jeep models. This flexibility helps the factory meet varied customer needs. Every Jeep leaves the line ready for the next phase.

Quality Control Measures

Quality checks happen at several points during production. Inspectors examine the fit and finish of every part. They test mechanical systems to ensure proper function. Any problem found leads to immediate fixes before moving forward.

Final inspections include road tests and safety checks. These tests confirm the Jeep’s durability and performance. The factory follows strict standards to keep customers safe. Quality control makes sure every Jeep is ready for adventure.

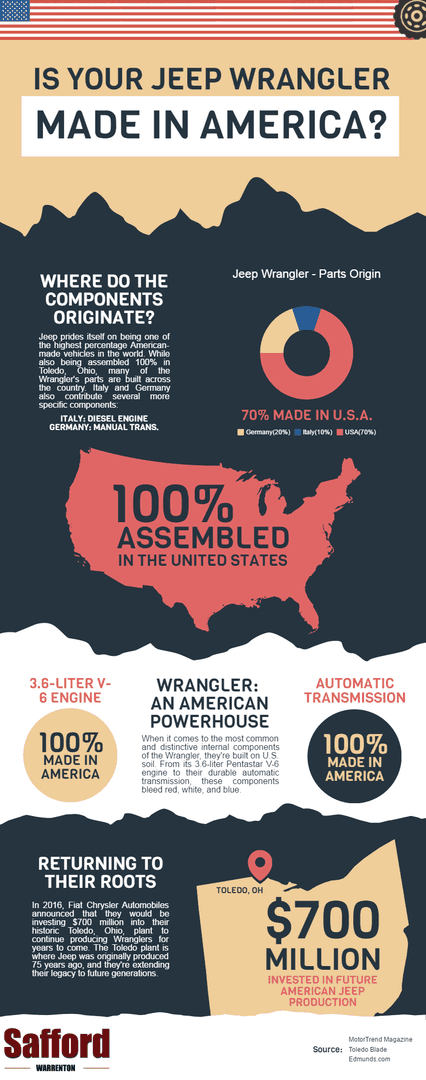

Parts Sourcing

Wrangler Jeeps are built with parts from many places. The sourcing of these parts plays a big role in their quality and performance. Jeep relies on a mix of domestic and international suppliers to get the best components. This balance helps keep the Wrangler strong and reliable.

Domestic Suppliers

Many parts for Wrangler Jeeps come from American companies. These suppliers provide key components like engines, transmissions, and suspension parts. Using local suppliers supports jobs and helps control the quality of parts. It also shortens delivery times, keeping production smooth and steady.

International Components

Some Wrangler parts come from outside the United States. Jeep works with trusted suppliers worldwide for electronics, tires, and other specialized parts. This global reach helps Jeep access advanced technology and materials. It also allows them to keep costs reasonable without losing quality.

Impact Of Location On Wrangler Design

The design of the Wrangler Jeep is shaped by where it is made and sold. Different locations bring unique needs and challenges. These factors guide how the Jeep is built and styled. Understanding this impact helps explain why Wranglers vary worldwide.

Regional Influences

Wrangler design reflects local culture and environment. In the United States, rugged off-road ability is a top priority. Harsh terrains and outdoor lifestyles shape the Jeep’s toughness and features. In other regions, climate and road types affect design choices.

For example, European models may focus more on fuel efficiency and size. Urban areas need compact, easy-to-drive vehicles. Safety standards also differ, influencing materials and technology. The region’s history with off-roading and adventure plays a role too.

Adaptations For Markets

Wranglers change to meet specific market rules and preferences. Engines and emissions systems adjust to local laws. Some countries require stricter pollution controls, leading to different powertrains. Interior options vary to suit customer tastes and comfort needs.

Features like navigation systems and climate control adapt to local languages and weather. In hotter regions, cooling systems get upgrades. Cold areas get better heating and insulation. These changes make Wranglers more practical and appealing worldwide.

Credit: www.saffordofwarrenton.com

Future Manufacturing Trends

The future of Wrangler Jeep manufacturing blends new technology with green practices. Factories will use smarter machines to build vehicles faster and better. These changes aim to improve quality and reduce waste. The industry focuses on making cars cleaner and more efficient.

These trends will shape how and where Wrangler Jeeps are made. They will bring more safety, speed, and care for the planet. The future factory will be a mix of innovation and responsibility.

Technological Innovations

Robots and automation will play a bigger role in Jeep production. Machines will handle more tasks with high precision. This cuts errors and saves time. Advanced software will help workers track every step of making a Jeep.

3D printing may be used to create parts quickly and cheaply. Smart sensors will monitor vehicle quality in real time. This technology will help keep Wrangler Jeeps reliable and strong.

Sustainability Efforts

Factories will adopt cleaner energy sources like solar and wind. This will lower pollution and reduce costs. Manufacturers will recycle materials to cut down on waste. They aim to make Jeep production more eco-friendly.

Using lighter and recycled materials will improve fuel efficiency. Companies will focus on reducing carbon footprints in every step. Sustainability is becoming a key priority in making Wrangler Jeeps.

Frequently Asked Questions

Where Are Wrangler Jeeps Manufactured?

Wrangler Jeeps are primarily manufactured in Toledo, Ohio, USA. The Toledo Assembly Complex has been the main production site for Jeep Wranglers since the early 1980s. This location ensures high-quality assembly and meets both domestic and international demand.

Are Wrangler Jeeps Made Only In The Usa?

While most Wrangler Jeeps are made in the USA, some models are assembled in other countries. However, the majority of production, especially for the North American market, remains in Toledo, Ohio. This maintains strict quality control and supports local manufacturing jobs.

Does Jeep Produce Wrangler In Multiple Factories?

Jeep Wrangler production is mainly concentrated in the Toledo Assembly Complex. There are no multiple factories producing Wrangler models on a large scale. This centralization helps maintain consistency and quality across all Wrangler vehicles.

What Materials Are Used In Wrangler Jeep Manufacturing?

Wrangler Jeeps use high-strength steel and aluminum for their body and frame. This combination provides durability and reduces overall vehicle weight. Quality materials ensure the Jeep’s ruggedness and off-road performance.

Conclusion

Wrangler Jeeps are mainly made in Toledo, Ohio, USA. This location has a long history of Jeep production. The factory uses skilled workers and modern technology. Each Jeep is built to handle tough roads and outdoor adventures. Knowing where they are made helps buyers trust the quality.

Jeep keeps improving its manufacturing to meet customer needs. So, the Wrangler remains a popular choice worldwide. The strong build and reliable origin make it stand out. This makes owning a Wrangler Jeep special for many drivers.